Summary of Testing Services

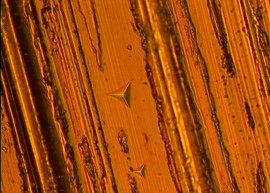

Adhesion Testing (stylus, single point technique)

- sample tested "as is", no pre-test handling and manipulation that affect the results

- provide failure load for chipping, cracking, delamination, etc

- better reproducibility and better comparative test than conventional shear strength testing

- technique can distinguish samples with difference in properties smaller than 1%

Adhesion Testing (tensile mode)

- Peel test

- Pull test

- Seal strength

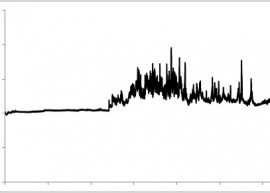

Coefficient of Friction

- Static and dynamic (kinetic)

- Moving sled on stationary plane technique

- ASTM D1894, G99, G133, G143, G171 and custom setups

Creep, Elastic Modulus & Stiffness

- creep is measured using either instrumented indentation, tensile testing or compression testing

- elastic modulus is measured using either instrumented indentation or tensile testing

- stiffness is measured using instrumented indentation

- instrumented indentation technique can distinguish samples with difference in properties smaller than 0.5%

Fracture Toughness & Cracking

- fracture toughness is measured using instrumented indentation

- scratch testing can also be used to study cracking (crack initiation and propagation)

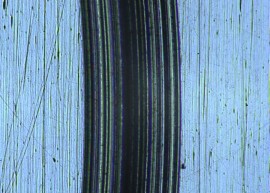

Hardness - Instrumented Indentation Testing (IIT) - Nanoindentation and Micro Indentation

- bulk materials and coatings

- glass, ceramic, metal, polymer, plastic, composite

- hard, soft, elastic materials

- technique can distinguish samples with difference in properties smaller than 0.5%

Hardness - Micro, Vickers

- bulk materials

- coating thicker than 100microns (0.004inch)

- thinner coatings possible on a polished cross-section

Hardness - Rockwell

- regular and superficial scales

- 1/100th point resolution

- estimation of tensile strength by indentation testing (metals)

Hardness - Shore durometer

- rubbers, elastomers, plastics/polymers

Instrumented Indentation Testing (IIT) - Nanoindentation and Micro Indentation

- bulk materials and coatings

- glass, ceramic, metal, polymer, plastic, composite

- hard, soft, elastic materials

- hardness, elastic modulus, stiffness, creep and fracture toughness

- properties in function of depth

- uniformity of material in function of depth

- results do not depend on residual imprint and operator

- technique can distinguish samples with difference in properties smaller than 0.5%

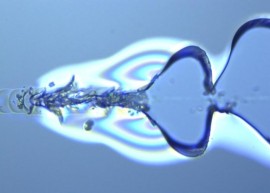

Mechanical Testing (tensile, compression, flexural/bending, shear)

- Standards and custom setups

- Adhesion

- Creep & relaxation

- Elongation

- Puncture resistance

- Pull-out force

- Push-out force

- Seal strength

- Tensile strength

- Break and rupture testing

- Cyclic testing

- Height measurement

- Single and multi-stage custom designed testing

Nanoindentation and Micro Indentation

- bulk materials and coatings

- glass, ceramic, metal, polymer, plastic, composite

- hard, soft, elastic materials

- hardness, elastic modulus, stiffness, creep and fracture toughness

- properties in function of depth

- uniformity of material in function of depth

- results do not depend on residual imprint and operator

- technique can distinguish samples with difference in properties smaller than 0.5%

Scratch Resistance Testing, comparative test for:

- cracking

- marring

- relative hardness

- scratch hardness

- permanent deformation/plastic deformation

- resistance to puncture

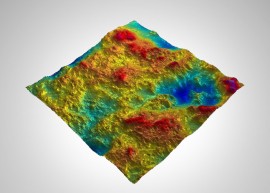

Wear & Abrasion Testing

- Standards and custom setups

- test path: circular or linear reciprocated

- kinetic coefficient of friction, with or without wear

- wear rate